Rogers History 1975 – 1982

Many thanks to Brian Pook who was Managing Director of Rogers between 1976 and 1982 for this history. This article and photographs are the copyright of Brian Pook and may not be reproduced elsewhere without his permission.

After 25 years ‘in exile’ I have been directed to this website by an old friend and hope to find the time to help a few people with history and technical advice ( without treading on toes or destroying too many peoples’ misapprehensions! ). I was Managing Director of Rogers from 1976 until 1982. I left the industry completely and have restored furniture/architectural fittings for the past 24 years, having just commenced ‘semi- retirement’. My period of involvement with Rogers spans the initial production of the LS3/5A,the volume production of the LS3/5A, the LS3/6 problems, its change to the Export Monitor, the aquisition of Chartwell in 1978, the creation in house of unique polypropylene and bextrene coned drive units, the creation of the Studio 1, the creation of the worldwide Rogers distribution. etc.,etc,.etc..

The stories concerning the BBC, KEF and the LS3/5A production could fill a book. I’m so sorry to report that Malcolm Sced, the Technical Director and Richard Ross, the Loudspeaker technical genius ( later MD ) have both passed away, so it seems important to pass on a few bits of info whilst I have the time and enthusiasm. I haven’t got time to write a book every evening, so I may be selective in how much I reply daily.

When I took over at Rogers they had been struggling to produce the LS3/6 BBC Monitor. Not only was the main bass unit unreliable, due to the BBC-defined construction, but Celestion were only able to spasmodically supply the HF1300 tweeters, which were selected to very tightly defined parameters. The only solution was to break away from the BBC design, seek a manufacturer to supply a special higher- powered, pressed-steel frame bass unit ( Dalesford ), make mods to accomodate more mainstream HF1300s and streamline numerous BBC quirks thus creating the Rogers Export Monitor. The performance of the bass units in terms of listening quality was never comparible to the LS3/6 due to the inferior cone profile and chassis. When Rogers bought the Chartwell company they were able to rescue the original BBC profile cone moulding tools from Hyder Cones and make high power bextrene- coned cast frame drive units in-house that were superior to the BBC LS3/6 design in every way. This was used to create the Rogers Studio 1.

I hope this provides some useful background. Obviously this is just a snapshot of a much bigger picture!

The Rogers History 1975 to 1982 – Part 1

This lengthy lead-in may at first appear irrelevant, but stick with it ! In the early 70’s I was the Director in charge of the Audio division of a specialist manufacturer called Electrosonic Limited ( an interesting google ). I designed theatre, studio and audiovisual sound equipment. For control applications I incorporated Teac multichannel tape machines, imported by a company called Acoustico Enterprises, whose owner was a Chinese entrepreneur called William Ling. They were also the first UK importer of Bose products, which I introduced into systems using the first professional Bose 800 products. As a result of my experience I was asked to accompany the European Bose Distributors to the first European Distributors’ meeting at Framingham, USA as their technical advisor. I therefore came to know William Ling very well and created for him the Bose PA systems used for the performances of the James Last Orchestra and the Bert Kaempfert Orchestra at the Royal Albert Hall. I then had a huge car accident ( driving head on into a lorry ) which kind of terminated my meteoric rise. After more than a year recovering I visited the Electronic Components Show in London and by chance met William Ling in the crowd. He said he had heard that Rogers were ‘in trouble’ and would I like to take an interest in running the company if he bought it. I was really still recovering from my accident and this seemed an opportunity for rejuvenation – little did I know what I was getting into !

So I visited Jim Rogers with William Ling and ‘took stock’ of the situation. At that time I was yet to hear from a young engineer employed by William Ling called Richard Ross —-

Intermission No 1

As I’ve had a hard day I won’t continue with the saga today but instead just enlarge on something Pete Sced’s mum

mentioned – the fact that at one time Rogers were rejecting 90% of the KEF B110 drive units !

When Rogers, manufacturing under my direction, put the LS3/5A into production a large number of the B110 drive units did not provide the expected performance and initially anything up to 30% of the B110s were rejected. KEF agreed to exchange them, since they were anxious to co-operate in view of the glory of the BBC association and their reputation. This was hardly efficient ,since we could only verify performance by testing the finished loudspeaker and then taking it apart, swopping the B110 and trying again! To our horror as production increased and the weather changed during the year more and more B110s were rejected, until it became almost impossible to maintain production. Laurie Fincham, the Technical Director of KEF, analysed the problem in conjunction with Malcolm Sced and came to a shock conclusion – the BBC had designed the LS3/5A using B110 drive units that were right to one end of the drive unit performance tolerances ( probably due to the weather at the time of year they were made ? ). The attitude of the BBC was that the LS3/5A was a finished design and could not be changed. To my relief and joy Laurie Fincham agreed that KEF would pre-test and select the B110 units for Rogers using computer performance analysis ( something KEF had pioneered) prior to delivery. You can imagine the difference this made in production efficiency and consistency. Many people have made nasty remarks about ‘how could Rogers make so many LS3/5A loudspeakers and still maintain quality?’. Our little secret has never been revealed until now.

Later, of course,( possibly after my time ) the BBC did work with KEF to modify the design slightly and eliminate the problem, thereby allowing the design to be more generally licenced. I have a sneaking suspicion that those 1976-1982 Rogers are the business ! In my saga I may reveal later why Raymond Cooke, the MD of KEF, was so helpful – a bit embarassing for him !

Of course, Kef had their own plans to better the LS3/5A and considered that it used old drive units and only had a limited life until such time as KEF brought out their own alternative. I remember visiting the KEF Suite at the Paris HiFi Show at a time when we were in big quantity LS3/5A production and had scheduled orders with KEF. When I entered the Suite Bob Cox, the KEF Sales Director, drew me to one side and in hushed tones advised me that I might need to review our drive unit orders because KEF were introducing their Reference 101 at the Show, which he proudly showed me. Such arrogance – but of course KEF believed their Computer Design was perfect – no need for silly things like endless hours of comparative listening at the BBC! I can allow history to be the judge of who was right!The Rogers History 1975 to 1982 – Part 2

Whilst Willian Ling negotiated with Jim Rogers the terms for purchase of Rogers Developments ( I never knew the details, unfortunately ) my concern was to investigate the financial health of the company, its products and their future potential. Whilst Jim Rogers seemed somewhat shell-shocked and isolated in his upstairs office,I spent hours with Macadie, Jim Roger’s fellow Director, analysing the accounts and the practical aspects of production. The poor chap had been single-handedly fighting to keep the company afloat and was exhausted. The Rogers Electronics were dated, but still in sluggish demand – the glimmer of hope for the future was the potential for the LS3/5A, if only it could be economically produced in quantity. I already knew the LS3/6 as a professional customer and had never been able to obtain adequate reliable supply, however I knew the Spendor BC1 (as a customer) and had ideas to build on the LS3/6 potential. Rogers had lost a large ammount of money preparing and purchasing components to produce the LS3/5 ( including full colour leaflets ) and had then waited for months whilst the BBC finalised the LS3/5A design, approved the production samples and granted a license to manufacture.

Based upon my optimism for the future potential of Rogers, rather than its past results, William Ling transfered £20,000 into the Rogers bank account and left me frantically working out a plan to keep creditors at bay and the ship afloat. Macadie and Jim Rogers were conspicuous by their absence ——-

As the company had been sliding towards bankruptcy Jim Rogers had been playing in his office with a cylindrical aluminium prototype loudspeaker enclosure which I understood had been developed by GEC, whose Hurst Laboratories had an anechoic chamber. I recall a frequent visitor, Bobby Fisher, as being important in some way, possibly as a GEC employee, but would appreciate any input that anyone can provide. Jim Rogers obviously had his own ideas for the future ! —-

Meanwhile I was able to use the sudden cash injection to briefly reassure the bank, re-establish component supply and pay the staff.I discovered that the company had taken considerable prepayment for amplifiers and tuners from M.O’Brien HiFi and AT Labs ( two volume retailers ) and had been unable to supply due to its financial crisis. One of my first acts was to supply these pre-paid back orders, purely on moral grounds and this was to have unforeseen future benefits —-

Meanwhile after a couple of weeks at the helm I received a surprise phone call – ‘ Hello , Mr Pook?, I’d like to introduce myself, I’ve been appointed the Receiver for Mr Ling’s Company, Acoustico Enterprises Ltd. I believe Rogers has an outstanding loan from the company of £20.000 and I’d like it repaid’ ——-

More to come —- meanwhile does anyone know the link between Rogers, a chinese laundry and a bean shoot factory?

The Rogers History 1975 to 1982 – Part 3

So there I was —– running a bankrupt company ‘owned’ by an absent volatile individual whose main trading company had gone into receivership. I had a large workforce to look after, the Rogers history and its reputation in my hands and no money – crumbs ! Wait till the Bank get wind of this !

Colin Marsh, the delivery driver, factory caretaker and general good guy, had let me know that Michael O’Brien, the Wimbledon HiFi retailer, was wealthy and interested in Rogers. Luckily, as I previously mentioned, I had looked after his prepaid orders and he was happy to talk. With an understandable degree of trepidation and doubt ( his accountant advised against the venture ) Michael O’Brien decided that he would buy the company from William Ling, Jim Rogers or whoever proved to have ownership !

Lawyers were briefed and a ‘sale’ meeting of all parties was tabled .The staff at the Sidcup metalshop were asked to arrange for all the heavy Plant (guillotines, power-presses,fly-presses,etc.,)to be transferred to the Catford factory yard, since the Sidcup factory would be excluded from the sale ( I had always believed it to be uneconomic ). On the appointed day a sale meeting was convened at the Rogers factory and at the same time a gigantic Beck and Politzer low loader pulled into the factory – ——-

The sale talks and the resultant legal ramifications commenced and whilst this was happening we watched out of the window the giant Scania tractor unit detach from the trailer ( overloaded with the huge Sidcup machinery ).It promptly jammed itself between the factory gateposts! As the talks proceeded we had the spectacle of a giant Beck & Politzer crane appear and lift the Scania lorry vertically from between the gateposts ( under searchlight, as night had fallen — — this was just like the movies ! )

As the meeting drew towards the intended sale a metaphorical hand- grenade was thrown in by Jim Rogers or Macadie, I can’t remember which,to the effect that the Borough of Lewisham had some time previously ‘levied distress’ on the company for non-payment of Rates, thereby making it illegal to sell any of the company’s assets. A bit of a shock ! How had Jim Rogers thought that he could sell the company to William Ling ? A good time to go home — pay the Rates and try again.Off we went leaving a trailer of heavy plant on the factory lawn —-

Next day, shock, horror,the front steady legs of the trailer on one side had been placed over a soakaway and it had sunk drunkenly five feet into the ground. It was now useless – twisted beyond salvation. Oh dear, another giant crane – and who was liable to pay Beck & Politzer ?

Michael O’Brien had wanted to save the company, but had been thwarted by the stupidity of the Rogers Directors —-

Meanwhile —- Lewisham council had got wind ,somehow ,of what was happening and sent in the bailiffs. This was the end ——–

The Rogers History 1975 to 1982 – Part 4

I just couldn’t leave things in mid-air – how would anyone sleep ?

The bailiffs arrived and were nice sensible guys, given that they were instructed to effectively clear the factory. With a bit of fast thinking, subterfuge and charm all BBC design data, prototypes and critical hardware,tooling, etc was spirited away ( hence Malcolm Sced’s home store ), thus ensuring that the bailiffs covered the debt by removing replaceable items, equipment and tools.Imagine the heartbreak of watching them remove a £7,000 Bruel & Kjaer measuring set as part of their booty !

The company appeared sunk. The workforce had to be made redundant and Rogers Developments cease trading – but how could we allow this to be the end ? How could I ever face the world again ? We knew from the bailiffs that everything would be taken to Greaves Auction Rooms at Tooting. This key factor led to a crazy idea – why not attend the auctions, buy back all the Rogers items, buy the Rogers name from the Rogers Receiver ( when appointed by the Bank ), lease the factory from the absentee landlord in Scotland, renegotiate the BBC LS3/5A licence and start again ? ( assuming that Michael O’Brien was willing to put up the money ! ) —– and this is exactly what we did.

It’s not every day that you buy a Bruel & Kjaer at auction for £300 !

We needed an instant trading vehicle overnight and Swisstone Electronics Limited was ‘on the shelf’ for immediate use – a rather bizarre name for a prestige British manufacturer ! I reckoned we could rebuild the company from a nucleus of six key people – myself, Malcolm Sced, Jim Elms ( production foreman ), Colin Marsh ( van driver extraordinaire ),Len Neville( former metal shop worker )and a.n.other ( I feel guilty now, in that I can’t be certain who the sixth person was ). Crucial to all this was the unswerving support of Michael O’Brien. I don’t know if he was sleeping too well, I’m sure I wasn’t. Another critical factor was the contribution of Michael’s superb Solicitor, who I shan’t mention by name, even though he is unlikely to be alive today. Later, his role was to become even more vital —-

Meanwhile both William Ling and Jim Rogers had their own plans —–

The Rogers History 1975 to 1982 – Part 5

Looking back it seems ridiculous that I resurrected Rogers with five other people ( a crucial one being Malcolm Sced ), thanks to Michael O’Brien’s financial gamble and the experience of his Solicitor. Within weeks we had re-employed an increasing number of former employees and resumed production. The substance and reputation of Michael plus my credibility on the telephone persuaded suppliers to come back ‘on board’.

At the same time Jim Rogers was putting his JR149 into production, initially using the ‘Rogers’ brand name, unaware (possibly)that we had purchased the title to the use of the Rogers brand name from the Receiver of Rogers Developments. This caused confusion and ill- feeling within the industry, since people perceived Jim Rogers to be the injured and duped party. Firm legal action was required to rectify this situation.

At the same time we had to deal with the little matter of a licence to manufacture the LS3/5A, since the licence had ceased with the demise of Rogers Developments and the BBC Secretariat were reluctant to be involved with any successor. I still vividly recall the meeting of myself, Michael O’Brien and his Solicitor with Mr Casson of the BBC Secretariat. He was anything but understanding and was presented with a combination of my ‘pleading’ and the more businesslike approach of Michael and his Solicitor. Legally he was obliged to be even-handed in his dealings with all interested parties with regard to licencing and Swisstone Electronics were granted a licence to manufacture the LS3/5A. At the same time it was pointed out that the BBC were granting the same licence to a Company started by former BBC employees called Chartwell ———

The Rogers History 1975 to 1982 – Part 6

As I’ve finally relaxed in preparation for festive celebrations, I thought it would be interesting to talk about another virtually unknown part of the Rogers tale – the way that Richard Ross’ honesty and Michael O’Brien’s bulldog-like determination saved the LS3/5A from a messy and uncertain future.

Equipped with a shiny new BBC LS3/5A licence its huge workforce of 6 people was slowly expanded in 1976 by re-employing former staff. Our focus was on re-establishing demand and achieving efficient production. It needed a combination of nerve and hard work to rebuild everything virtually from scratch, whilst at the same time calming the uncertainty of UK retailers .

We decided it would be wise to concentrate on establishing overseas distribution, especially in view of possible dealer resistance to selling the products of a company owned by another dealer . At the same time we were continually `looking over our shoulder’ at the activities of both JR and Chartwell ——

Suddenly, out of the blue, I received a telephone call from a Mr Ross, who introduced himself as an employee of William Ling . He explained that he had been working as an engineer for him and had become concerned that William Ling was preparing to manufacture counterfeit LS3/5As in Hong Kong ! Oh no ! It was that man again ! It is not hard to imagine the damage that this action would have had on the reputation of the BBC, the LS3/5A and Rogers. Michael O’Brien reacted swiftly ( and expensively ) to deal with the situation. Legal action was taken, both in England and Hong Kong, to prevent William Ling `passing off’ any Rogers or BBC products. My trip with Michael O’Brien and his Solicitor to take instruction at Barristers Chambers in Lincoln’s Inn Fields was very expensively special – not something I wish to repeat, but an experience I shall never forget ! I cannot recall the final huge legal bill, but it’s probably best forgotten ! I am pleased to report that we never heard of Mr Ling again ——

This sorry episode had one very happy outcome – I had met Richard Ross, asessed his special talents and been able eventually to offer him a job. He was to become head of Rogers loudspeaker design and was one of the most naturally gifted engineers that I have ever met. I was delighted when he became Managing Director after my departure in 1982.

During the stress and strain of our first year of revived production I had been cultivating export sales as the key to the future success of Rogers. We were to achieve huge sales in Japan and the USA, which I’ll talk more about soon.

Whilst the Rogers production was growing a new manufacturer was becoming established – Chartwell. Led by David Stebbings, an ex-BBC Engineer, this new company based on Mitcham Common not only had a BBC LS3/5A licence, but knowledge of the new polypropylene cone technology developed by Dudley Harwood, the BBC Design Engineer ( at that time ). Chartwell had found finance to `jump in at the deep end’ and established facilities to manufacture their own drive units, including vacuum-forming the cones in both bextrene and polypropylene. They were to find, to their considerable cost, that there is a huge difference between one-off research and reliable volume production —–

Here is the link between Rogers, a laundry and a bean shoot factory — —–

A Director of Chartwell and its primary source of finance was a charming Chinese gentleman called Joseph Pau. He was the owner of a bean shoot factory in North London which he had created in an old laundry. He was a major supplier of bean shoots to restaurants and supermarkets. The speed of bean shoot growth and the return on capital employed is phenomenal and Chartwell proved the ideal means of soaking up the bean shoot profits ——-

The Rogers History 1975 to 1982 – Part 7

I’ve replied to a query on the Group regarding the Rogers Export Monitor and this seems a good time to give some background to the LS3/6 – Export Monitor – Compact Monitor – Studio 1 Rogers bextrene – coned monitor lineage.

Between 1970 and 1975, when I was designing one-off systems at Electrosonic Limited, my great love, on the rare occasions when I could get supplied, was the Rogers BBC LS3/6. One mention of those magical words – Dudley Harwood and the BBC – and the red mist would descend and I’d wait weeks for a pair of the Rogers loudspeakers when Spendor BC1s were predictably available. The performance compromises were infuriating ( the poor power handling, limited maximum s.p.l., the critical room placement, the need for special stands, the `plummy’ overripe base on certain source material and hardware, the unusual load impedance ) and yet listening could be very special.

Having resurrected Rogers in 1975, here was my big opportunity to sort things out ( or so I thought ). There we were, all 6 of us, dreaming of realising the sales potential of the BBC LS3/6 and steaming into quantity production, except for the small matter of complying with the BBC design to the letter — it didn’t take long to realise that Rogers should never had been making the LS3/6 !

I think it’s best if I list a few headaches —

- The hand made bass unit was notoriously unreliable – – – –

- The voice coil was wound on a paper former at Rogers using glues that would be laughable today.

- The spider would sag, causing the voice coil to rub.

- Supply of the Celestion HF1300 tweeter was almost non-existent, as Celestion had to specially select a tiny percentage of production units in order to meet the BBC specification.

- The crossover was complex and expensive to produce. It presented an inductive, transformer coupled load to the amplifier, which upset some amplifiers.

- The acoustic balance would prove bass heavy in most placements. This was not helped by the bass reflex design( the bass balance and damping were chosen by the BBC for their studio requirements ).

- It was easy to solve the problem by ceasing production, but there was an established reputation and demand for a loudspeaker to the LS3/6 concept.

The arrival of Richard Ross gave fresh input into the groundwork investigations of Malcolm Sced into designing an LS3/6 derivative, essentially for overseas markets. An engineering Company in Yorkshire, Dalesford, agreed to manufacture a unique 8″ bass drive unit for Rogers. Celestion agreed quantity HF1300 tweeter supply to a more practical specification. Richard redesigned the crossover using ferrite cored inductors. Hence the creation of the Rogers Export Monitor. By making a loudspeaker that made no claims to BBC design, handled power and had `tighter’ bass, sales went from strength to strength.

The lessons learnt enabled an `economy’ loudspeaker to be designed – the Rogers Compact Monitor. This was two thirds of the size of an LS3/6, an IB cabinet design, and used a fabric-domed Audax tweeter with a Dalesford bextrene coned bass unit. Thirty years later my 90 year old father still uses a pair – they still sound great, shame his hearing is almost non-existent !

During 1976/1977 production of the Rogers loudspeakers became predictable, efficient and a world wide success, especially that little miracle, the LS3/5A. However we(the Rogers triumvirate of myself, Malcolm Sced and Richard Ross) knew that the LS3/6 had special qualities that had been lost and we knew why —– The key to the LS3/6 performance was the 8″ bextrene coned BBC designed bass unit. The cone profile and thickness, especially in the neck region are crucial to achieving the smooth,extended HF range of the bass unit , which allows an unusually high crossover frequency and a wonderful mid-range. The cones were moulded for Rogers, using their own tools, by Hyder Cones. The only way to resurrect that quality was to manufacture our own bass unit again with our own

unique cone and cast chassis. Meanwhile Chartwell had established in Mitcham, south London,a complete facility for moulding cones and manufacturing their own bextrene and polypropylene coned drive

units ————

The Studio 1 would be more special than people realised ——–

The Rogers History 1975 to 1982 – Part 8

Mentioning the Rogers Export Monitor is a handy lead–in to the thing that generated the profits that made the purchase of Chartwell possible – the Rogers export sales success. Once production was re- established in 1976 a deliberate policy of export sales emphasis was implemented. Within two years a combination of hard work and luck resulted in 50% of loudspeaker production going to Japan and the USA. The luck element ? – the discovery and cultivation of two surprise distribution opportunities.

Within a few months of achieving efficient production I received a surprise telephone call from a Japanese businessman who was visiting London and wished to visit the factory and discuss `Rogers’. The factory was operated by a tiny workforce and looked like the aftermath of a burglary, but what was there to lose? I gave him directions on the use of British Rail (!) and he duly appeared at our factory door. The visitor, Toshihiko Mori, proved to be the most charming, friendly and enthusiastic person one could wish to meet. A true friendship that continues even today, over 30 years later. He proposed Japanese Distribution of Rogers through his business, Odex Japan Company and agreed an initial order.

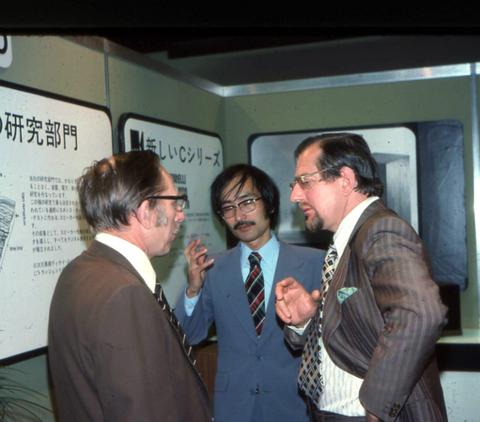

Almost simultaneously the Federation of British Audio in conjunction with the Board of Trade and the British Embassy in Tokyo announced that they were organizing the first exhibition in Japan dedicated exclusively to British HiFi.

With our newly agreed distribution this provided the perfect launch pad for our fledgling operation. Imagine my amazement on arrival in Tokyo to find that our new distributor had made a huge investment in both personnel and promotion – a fact that was somewhat embarrassing at such an early stage and that must have caused gossip amongst our fellow British exhibitors. When showing the ageing President of the Japan Audio Society our stand, Raymond Cooke, the MD of KEF made sure to point out the amusingly primitive BBC construction techniques of the LS3/6 – still, I had the last laugh, in terms of our Japanese sales!

Toshi Mori lived up to every expectation and I’ll relate some further tales later —-

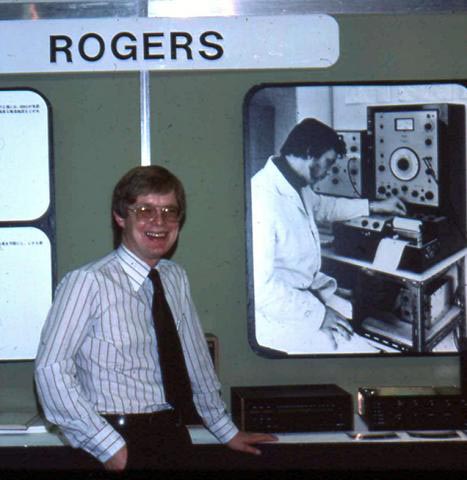

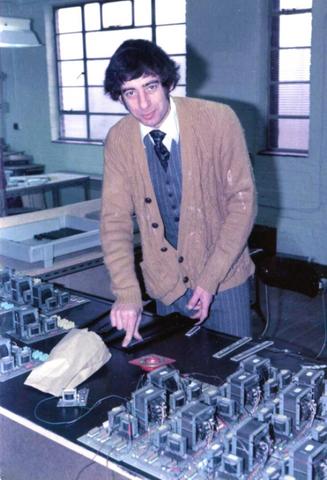

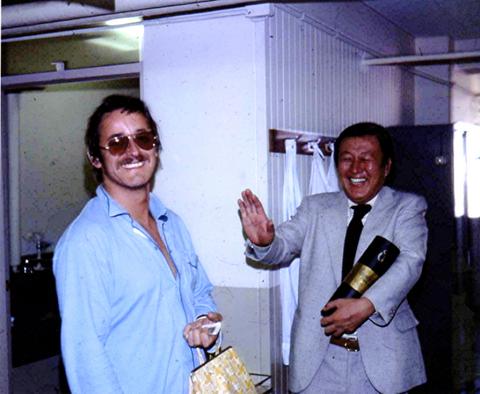

I’ve posted some photos of that first Tokyo Show in my photo gallery.

The United States of America

During the early days of 1976 Rogers UK market sales were hard work, due to the recent upheavals and the reluctance of UK dealers to support a company owned by a fellow shop ( especially one known for heavy discounting ), even though in practice Michael O’Brien proved honourable in maintaining a clean, arms length relationship. However, some shops were supportive, especially Reading HiFi, who had realised the performance and potential of the LS3/5A. Out of the blue, the owners, John Bradford and Edward Toms, phoned to arrange a meeting at the factory to make a proposal – that they would sell up and both move their families to California to establish US Rogers Distribution ! John had dual nationality, since his father was American and his mother English. We agreed exclusive Rogers Distribution and off they moved to San Diego, to capitalize on USA LS3/5A reviews that were the stuff of dreams. They invested in a stand at the June Consumer Electronics Show in Chicago and launched Reference Monitor International onto the US market as the official exclusive Rogers Distributor. Further tales to follow ——-

I’ll post an amusing picture of John Bradford in Tokyo later, when I relate a tale of a typhoon, 30 deaths, suspected cholera, an isolation hospital and a living nightmare !

The Rogers History 1975 to 1982 – Part 9

For the first two years of the Rogers re-incarnation I focused on maximizing Rogers export sales ( after all, UK Hi Fi Outlets were reluctant to buy the products of a company owned by a rival retailer ! ). Distributors were established in the USA and Japan, as I previously mentioned, but also in Hong Kong, Singapore, Canada, France, Norway, Switzerland, Italy, and later in Taiwan, Thailand, Spain, Germany and Greece.

Whilst efficient, profitable production was the priority, Richard Ross, Malcolm Sced and myself became increasingly paranoid about the threat of a new wonder development – the polypropylene loudspeaker cone. My recollection of events may be rather sketchy compared to the detail known by Malcolm and Richard, but hopefully I can capture the essential events and atmosphere.

It started with news that Dudley Harwood and the BBC had developed techniques that enabled the use of Polypropylene as a loudspeaker cone. The material enabled the construction of drive units that were more efficient ( polypropylene is lighter than bextrene ) and exhibited lower colouration ( although some people might say different colouration ! ). Rumours spread that a company called Chartwell had a licence to use this new development and employed ex- BBC engineers. Was the use of polypropylene in this way patented ? Would the BBC Licence it ? Did Dudley Harwood have plans to form his own company and use it ? Did Dudley Harwood have exclusive rights to the use of it ? Were the BBC planning designs using it and would they be licensing the manufacture of them ?

Insiders related stories of David Stebbings, the Chartwell MD and an ex-BBC engineer, having BBC inside knowledge in forming Chartwell , unlimited finance from Joseph Pau, a Chinese businessman and a shiny new LS3/5A licence. Not the sort of situation for a good night’s sleep. Things could only get worse ———

In 1977 we heard that an Iranian businessman, Farad Azima had formed the Mission brand manufacturing company and was soon to start producing polypropylene – coned loudspeakers. Had he a licence to use the material ? Was one necessary ? Who was he ? Was he friends with David Stebbings ? At the same time we heard that Infinity, the USA loudspeaker manufacturer, were about to use polypropylene and were rumoured to reject any patent claims.

Meanwhile Chartwell had commenced production by selling LS3/5A loudspeakers `kits’ to BBC employees, something that disgusted us. We knew from extensive production experience that the performance would be compromised without selection of drive units and experienced calibration and adjustment. How could the BBC permit this violation of the LS3/5A ?

This was the stuff of nightmares ! We were making excellent profits and `keeping our heads down’. The Hi Fi industry must have considered us upstarts with negligible sales, let alone profits ( if only they knew ! ) . We now had a competitor with BBC friends. Mission were growing stronger, winning friends in the media and about to use polypropylene.

We felt destabilized by the threat of the unknown and our need to guarantee a stable future for the Rogers Loudspeakers.

If only we had the means of making our own drive units.

If only we knew more about the new polypropylene technology.

If only we had bigger premises with an anechoic chamber.

Imagine my amazement in 1978 on hearing that their bank had placed Chartwell into Receivership ———

To be continued…….