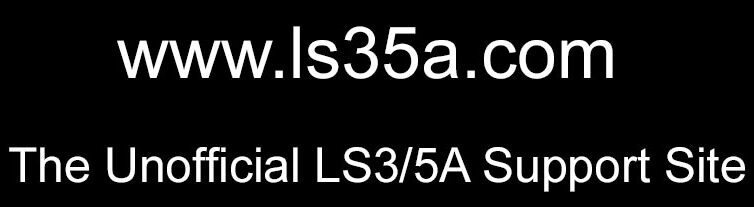

Brian Pook holds a vacuum-formed polypropylene diaphragm.

You’ll be amazed at how quickly the polypropylene cones pop up right before your eyes!

Once inside the factory, we were first shown the polypropylene cone manufacturing process, which is of great interest to music lovers. Just like we saw with the LS5/8, how is the white, translucent polypropylene made?

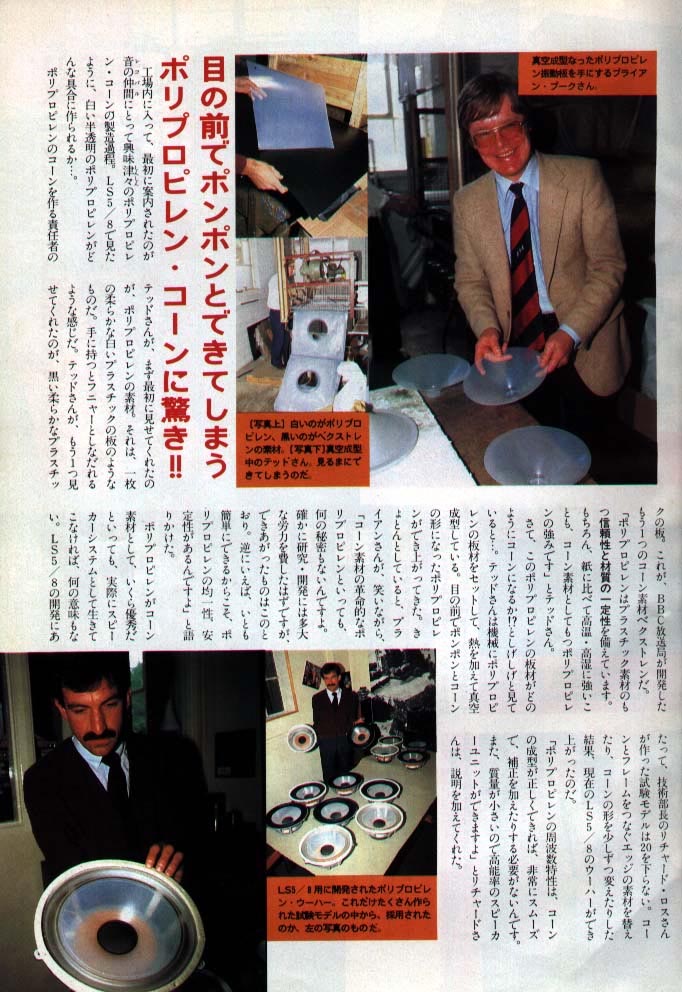

The first thing Ted showed me was a polypropylene material. It was like a soft white plastic plate. When I held it in my hand, it felt like it was floppy and flexible. Ted then showed me another thing, a black soft plastic plate.

[Photo above] The white material is polypropylene, and the black material is Bextrene. [Photo below] Ted in the middle of vacuum molding. It’s done in the blink of an eye.

“There’s no secret to it. It certainly took a lot of effort in research and development, but here’s the finished product. On the other hand, it’s precisely because it’s so easy to make that polypropylene is so uniform and stable,” he said.

No matter how excellent polypropylene is as a cone material, it is meaningless unless it is actually used in a speaker system.

This is Bextrene, another cone material developed by the BBC. “Polypropylene is a plastic material.

“It has high reliability and consistency of material. Of course, polypropylene’s strength as a cone material is that it is more resistant to high and low temperatures than paper,” says Ted.

Well, how does this polypropylene sheet material turn into a cone? I was watching closely… Ted set the polypropylene sheet material in the machine, heated it, and vacuum molded it. The polypropylene sheet was shaped like a cone right before my eyes.

The design is coming together.

While I was looking confused,

Ian laughed,

“Revolutionary cone material

“The frequency response of polypropylene is very smooth, once the cone is moulded correctly, so no corrections are needed. Also, its small mass allows for a highly efficient speaker unit,” Richard adds.

The polypropylene woofer developed for the LS5/1. The one in the photo on the left seems to have been selected from among the many test models made.

Technical Director Richard Ross created no less than 20 test models, changing the material of the edge connecting the cone to the frame and slightly modifying the shape of the cone, and as a result the current LS5/8 woofer was created.